Highlights:

- Bright luster, brilliant color

our innovative package-dyed technique ensures that the finished rayon yarn is much Brighter on luster than Dope-dyed (solution-dyed) rayon yarn.

- Maximum color range

Regular colors > 2000, there is almost no limits on color; the most important point is that we are able to dye and match to the customers’ colors, it’s so easy to develop the new colors.

- Exact color-matching, good color-consistency on repeated lots

The computerized color-matching system & other laboratory appliances help us to decide the optimized recipe of color; the digital dyestuff dosing & weighing system & automatic dyeing machines ensure to minimize the color variation & difference during dyeing process. The recipe database management system stored the individual recipe for each customer, it will help us to maximize the color-consistency on repeated lots.

- Flexible dye-lot size

Minimum dye-lot size: < 120.00kgs per color

- Competitive prices

Innovative low bath-ratio dyeing technique, shorter dyeing period, recycled water help us to cut down the production cost, improve the productivity efficiently.

- Eco-friendly

Only qualified reactive dye is used! AZO-free, dyed rayon filament yarn is compliance with Swiss Oeko-Tex standard 100.

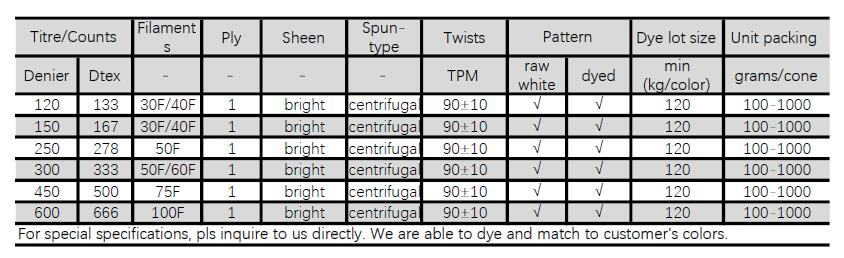

Specification:

| Titre/Counts | Filaments | Ply | Sheen | Spun-type | Twists | Pattern | Dye lot size | Unit packing | ||

| Denier | Dtex | – | – | – | – | TPM | raw white | dyed | min (kg/color) | grams/cone |

| 120 | 133 | 30F/40F | 1 | bright | centrifugal | 90±10 | √ | √ | 120 | 100-1000 |

| 150 | 167 | 30F/40F | 1 | bright | centrifugal | 90±10 | √ | √ | 120 | 100-1000 |

| 250 | 278 | 50F | 1 | bright | centrifugal | 90±10 | √ | √ | 120 | 100-1000 |

| 300 | 333 | 50F/60F | 1 | bright | centrifugal | 90±10 | √ | √ | 120 | 100-1000 |

| 450 | 500 | 75F | 1 | bright | centrifugal | 90±10 | √ | √ | 120 | 100-1000 |

| 600 | 666 | 100F | 1 | bright | centrifugal | 90±10 | √ | √ | 120 | 100-1000 |

| For special specifications, pls inquire to us directly. We are able to dye and match to customer’s colors. | ||||||||||

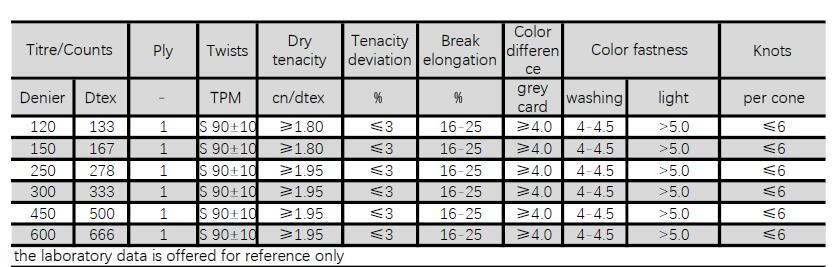

Technical indices:

| Titre/Counts | Ply | Twists | Dry tenacity | Tenacity deviation | Break elongation | Color difference | Color fastness | Knots | ||

| Denier | Dtex | – | TPM | cn/dtex | % | % | grey card | washing | light | per cone |

| 120 | 133 | 1 | S 90±10 | ≥1.80 | ≤3 | 16-25 | ≥4.0 | 4-4.5 | >5.0 | ≤6 |

| 150 | 167 | 1 | S 90±10 | ≥1.80 | ≤3 | 16-25 | ≥4.0 | 4-4.5 | >5.0 | ≤6 |

| 250 | 278 | 1 | S 90±10 | ≥1.95 | ≤3 | 16-25 | ≥4.0 | 4-4.5 | >5.0 | ≤6 |

| 300 | 333 | 1 | S 90±10 | ≥1.95 | ≤3 | 16-25 | ≥4.0 | 4-4.5 | >5.0 | ≤6 |

| 450 | 500 | 1 | S 90±10 | ≥1.95 | ≤3 | 16-25 | ≥4.0 | 4-4.5 | >5.0 | ≤6 |

| 600 | 666 | 1 | S 90±10 | ≥1.95 | ≤3 | 16-25 | ≥4.0 | 4-4.5 | >5.0 | ≤6 |

| the laboratory data is offered for reference only | ||||||||||

Application:

- Weaving –Georgette, crepe, satin, ribbon

- Knitting –Warp knitting, weft knitting fabrics

- Embroidering –Twisted rayon filament yarn is widely used for multi-head & Schiffli embroidering

- Braiding –Tassel, fringes, elastic tapes